With over 300 million in potential value for artificial intelligence in the supply chain management (SCM) field, organizations globally seek to leverage the technology to improve processes and realize cost savings throughout their SCM systems.

Main areas in an SCM system where AI can reduce costs and improve outputs

As mentioned in our recent blog “The power of AI to enable autonomous supply chain,” there are three crucial areas for organizations to focus on when it comes to autonomous supply chain: demand forecasting, logistics network & warehouse optimization, and sourcing & procurement.

Diverse results and potential value vary by industry, company, and use case. They are estimated as follows:

- Demand forecasting: Predicting demand across multiple product segments and geographies, as well as ensuring that plans get executed and can adapt to variability effects (such as demand shocks, production stoppages, and transportation disruption) promptly. The potential savings are generally well over 10% of supply chain operational costs and over 20% reduction in supply chain working capital. Typical impacts (non-exhaustive) are spread all over the supply chain. However, increasing forecasting accuracy can reduce average days of inventory and lead times while increasing promotion and marketing effectiveness and supplier compliance rate.

- Inventory management and optimization: AI can enable companies to balance trade-offs across functions and decrease operational and inventory costs by linking together multiple areas, including logistics, production, procurement, and marketing and sales. Potential savings typically range from a 10 to 50% reduction in working inventory capital and over 10% in operational inventory costs. Inventory turnover and warehousing needs can be materially reduced.

- Labor optimization: The time and effort required to schedule workers is a major pain point for many companies. AI-driven scheduling solutions can help alleviate some of these problems by providing a more efficient way of managing workforce data. By using machine learning algorithms, they can consider standard shifts and other relevant information about employees’ availability to create a more fair schedule. Overtime reduction, stable workload, and efficiency improvements are easily captured by AI.

- Route optimization for distribution: AI systems have been used to help optimize delivery routes for years, but they are typically limited to individual deliveries. In contrast, AI platforms can optimize an entire fleet of vehicles—which is why they have become valuable to companies that rely on timely shipments. The algorithm can consider several variables, such as traffic, shipment data, and geographical and environmental information streams. Typically the average mileage will be reduced as well as the secondary logistics needs.

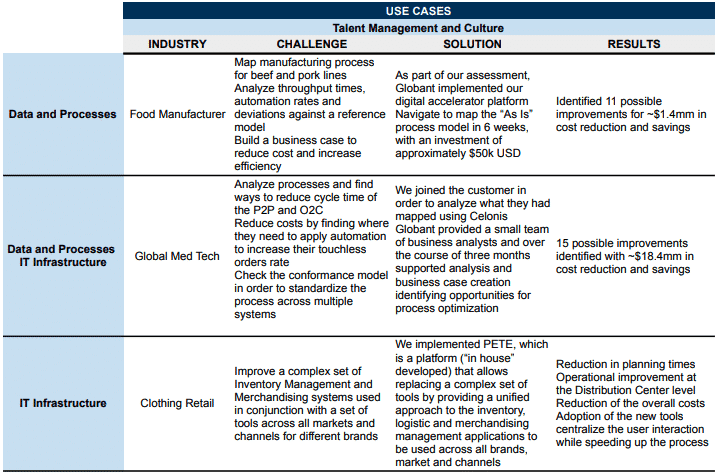

For years, Globant has been advising clients on how to implement AI and assess potential impacts we see in the Supply Chain industry. Some of these client cases include:

Table 1. Globant’s use cases for AI implementation in Supply Chain

Conclusion

Leveraging artificial intelligence to boost supply chain capabilities allows companies to minimize costs while increasing the outputs of their systems. With years of experience analyzing, implementing, and evaluating supply chain systems, the Business Hacking Studio at Globant creates opportunities for organizations to build autonomous supply chains. Learn more about the Business Hacking studio here.